Medical devices—from portable ultrasound machines to advanced surgical robots—depend on reliable motion control to deliver accurate diagnostics and treatment. At the heart of many of these devices lies a gear motor, the unsung hero that translates electrical energy into precise, smooth movement. Choosing the right gear motor can cut production costs, extend product life, and boost performance, making a tangible difference in both the bottom line and patient care.

In an era where healthcare budgets are tight and technology is rapidly evolving, manufacturers and hospitals are looking for every edge to reduce expenses without compromising quality. Gear motor selection is one of the most powerful yet often overlooked levers in this pursuit.

Medical equipment often requires specific traits: quiet operation, consistent torque, long life, and minimal maintenance. A gear motor that meets these needs can:

When picking a gear motor for medical devices, focus on these four core aspects:

Identify the maximum load the motor must handle and the required speed range. For instance, a patient‑monitoring exoskeleton needs smooth, low‑speed torque for gentle support, while a surgical drill demands high speed and precise control.

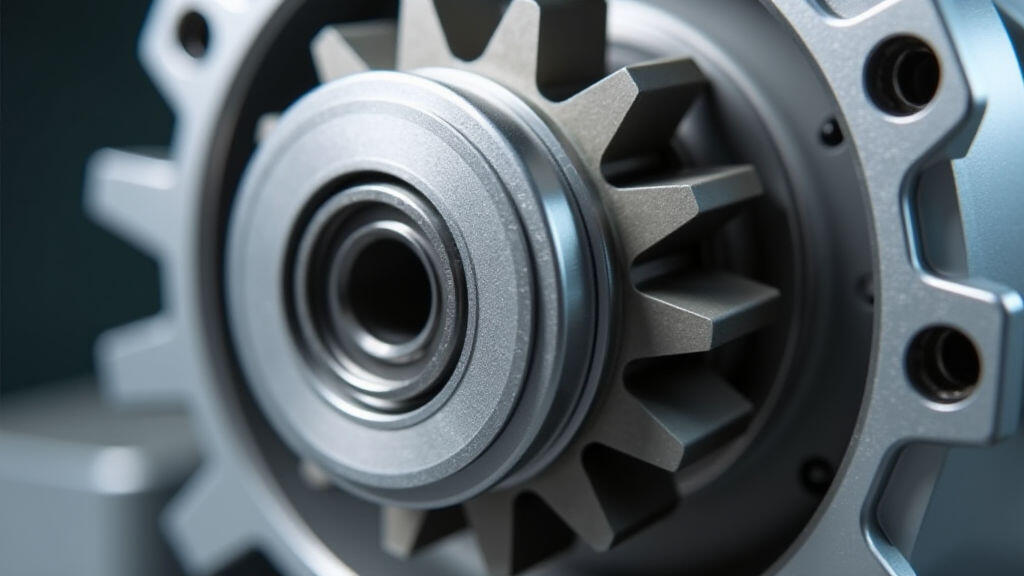

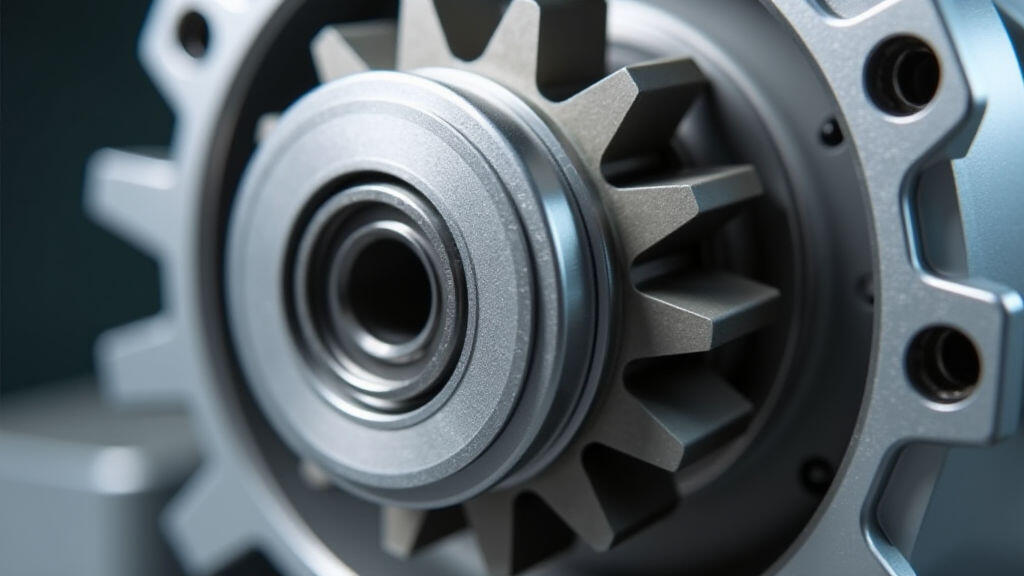

Planetary gearboxes are common in medical gear motors due to their compactness and high efficiency. Use materials like stainless steel or titanium alloys for gears and housings to resist corrosion and meet sterilization standards.

Integrate the motor with modern control systems—such as stepper or servo drives—that can translate clinical instructions into accurate, repeatable motion. Look for features like built‑in resolution sensors or the ability to support high‑resolution encoders.

Medical gear motors often run continuously in tightly packed enclosures. Choose designs that dissipate heat efficiently—through heat sinks, fan‐free airflow paths, or integrated thermal compounds—to avoid overheating and prolong lifespan.

One diagnostic company faced soaring power bills and frequent motor replacements in its portable ultrasound probes. After a detailed review, they switched from a traditional spur gear motor to a high‑efficiency planetary gear motor featuring a sealed aluminum housing and ceramic bearings.

The transition proved a win‑win for both the manufacturer—who reduced per‑unit costs—and hospitals—who enjoyed longer probe uptime and higher diagnostic fidelity.

Beyond cost and efficiency, gear motors play a crucial role in a device’s environmental footprint. Energy‑saving motors lower greenhouse gas emissions associated with electricity usage. Moreover, choosing motors that require less frequent replacement reduces electronic waste.

Designers can also adopt modular motor systems, allowing future upgrades without discarding entire units. This approach embraces the “repair‑and‑upgrade” philosophy, keeping devices in service longer and reducing the need for new purchases.

Recent advances in sensor technology and AI are shaping the next generation of gear motors:

These innovations point to a future where gear motors are not merely mechanical components but intelligent partners in patient care.

Choosing the right gear motor can unlock significant savings and performance gains for medical equipment manufacturers and healthcare providers alike. By evaluating torque and speed needs, selecting superior gearbox designs, ensuring compatibility with advanced control systems, and prioritizing thermal durability, teams can cut energy consumption, reduce maintenance costs, and deliver more reliable devices.

As the medical field continues to embrace sustainable practices and AI‑driven automation, intelligent gear motors will be central to the next wave of innovations. Investing in thoughtful gear motor selection today not only strengthens a product’s competitiveness but also supports a healthier, more efficient tomorrow for patients and clinicians worldwide.

Leave A Reply

Your email address will not be published. Required fiels are marked